Introduction to Industrial Endoscopes

Industrial endoscopes, also known as borescopes, are indispensable tools in industries requiring detailed visual inspections of hard-to-reach areas. These devices enhance precision, reduce inspection time, and ensure operational efficiency. From manufacturing to aviation, their applications are diverse. As demand grows globally, identifying reliable exporters becomes crucial for businesses seeking quality and innovation.

Why Industrial Endoscopes Are Essential

Industrial endoscopes help professionals detect flaws, assess wear and tear, and ensure safety. They are widely used in sectors like oil and gas, aerospace, and automotive. The ability to inspect confined spaces without dismantling machinery saves time and reduces costs. Advanced models equipped with high-definition cameras and articulation features provide unparalleled clarity, elevating inspection standards.

Key Features to Look for in Industrial Endoscopes

When selecting an industrial endoscope, features like image resolution, flexibility, and durability matter. High-definition imaging ensures clear visuals, while articulation allows maneuverability in tight spaces. Devices made from robust materials can withstand harsh environments. Additional features such as LED lighting, wireless connectivity, and compatibility with software platforms enhance usability and efficiency.

Global Demand for Industrial Endoscopes in 2024

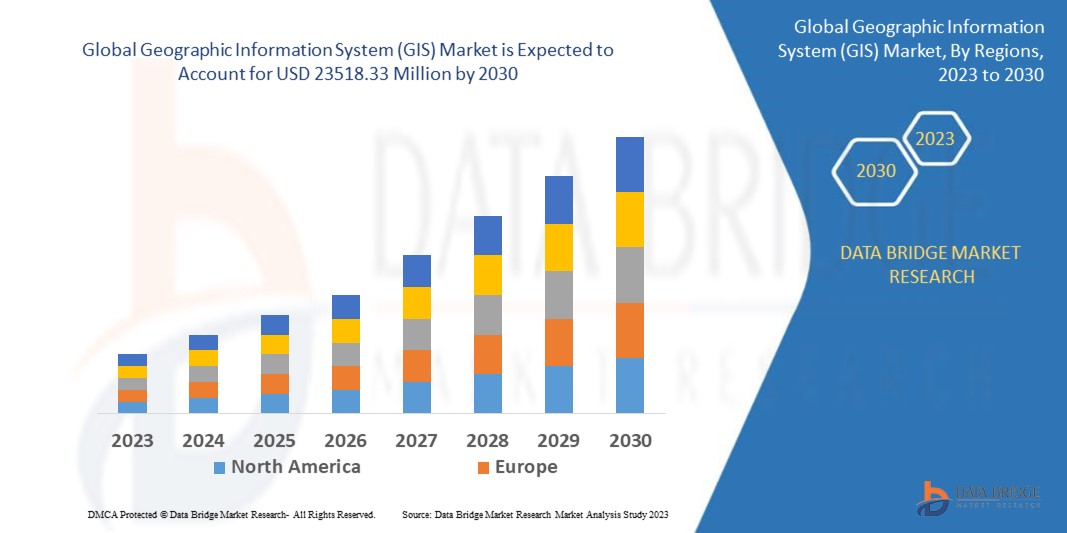

The market for industrial endoscopes is experiencing exponential growth due to rising industrial automation and stringent safety regulations. Emerging economies in Asia, Africa, and South America are adopting these tools rapidly. This surge in demand highlights the importance of exporters capable of delivering reliable, cutting-edge products to meet evolving industry requirements.

Top Industrial Endoscope Exporters to Watch

Identifying top exporters involves evaluating their innovation, quality standards, and customer service. In 2024, several companies stand out for their exceptional offerings and market reach. Their commitment to precision, durability, and advanced technology makes them leaders in this niche.

1. Olympus Corporation

Olympus Corporation, headquartered in Japan, is a pioneer in industrial endoscopy. Their products are renowned for cutting-edge imaging and ergonomic design. With a robust global distribution network, Olympus caters to industries like aviation, power generation, and manufacturing. Their continuous investment in R&D ensures innovative solutions for complex inspection needs.

2. GE Inspection Technologies

GE Inspection Technologies offers a comprehensive range of industrial endoscopes tailored for diverse applications. Known for their durability and clarity, GE’s products are preferred in oil and gas, automotive, and aerospace industries. The company emphasizes user-friendly designs, ensuring efficiency and ease of operation.

3. Karl Storz

Germany-based Karl Storz specializes in high-quality industrial endoscopes with a focus on precision engineering. Their products feature advanced optics and versatile articulation. With decades of experience, Karl Storz provides reliable solutions, earning trust across industries such as pharmaceuticals and manufacturing.

4. ViewTech Borescopes

ViewTech Borescopes, an American company, has gained recognition for its affordable yet high-performing devices. They offer flexible rental and purchase options, making their products accessible to businesses of all sizes. ViewTech’s emphasis on customer support and training further solidifies its position in the market.

5. Mitcorp

Mitcorp, a Taiwan-based exporter, is celebrated for its innovative industrial endoscopes. Their products integrate advanced imaging technology and robust construction, ensuring reliability in challenging conditions. Mitcorp’s commitment to sustainability and eco-friendly practices sets them apart in the competitive landscape.

Emerging Trends in Industrial Endoscopy

The industrial endoscope market is evolving with trends like AI integration, improved connectivity, and miniaturization. AI-powered image analysis enables real-time defect detection, enhancing accuracy. Wireless endoscopes with cloud integration simplify data sharing, while compact designs improve portability. These trends are reshaping the inspection process, driving demand for advanced solutions.

Factors to Consider When Choosing an Exporter

Selecting an exporter involves evaluating their product range, certification, and after-sales support. Certifications like ISO and CE ensure adherence to quality standards. Comprehensive after-sales services, including training and maintenance, are vital for long-term efficiency. Additionally, exporters offering customization cater better to specific industry needs.

The Role of Technology in Shaping the Future

Technological advancements are propelling the industrial endoscopy industry forward. High-definition imaging, 3D mapping, and remote operation capabilities are revolutionizing inspections. Exporters investing in technology-driven solutions are better equipped to meet the demands of modern industries.

Challenges Faced by Exporters

Despite their growth, industrial endoscope exporter face challenges such as supply chain disruptions, stringent regulations, and evolving customer expectations. Overcoming these hurdles requires adaptability, strategic partnerships, and a focus on innovation. Exporters addressing these challenges successfully will remain competitive in the global market.

Conclusion

Hd industrial endoscope are vital tools driving efficiency and safety across industries. As demand continues to rise in 2024, businesses must partner with exporters known for quality, innovation, and reliability. Companies like Olympus, GE Inspection Technologies, and Mitcorp exemplify excellence in this field. By staying abreast of emerging trends and investing in technology, these exporters are setting new benchmarks in industrial inspection.