Polybutylene Terephthalate (PBT) is a thermoplastic engineering polymer that is increasingly recognized for its versatility, durability, and performance in various applications. A member of the polyester family, PBT is widely used in automotive, electronics, electrical, and consumer goods industries due to its excellent mechanical properties, electrical insulation capabilities, and resistance to heat, chemicals, and wear. The Polybutylene Terephthalate (PBT) market outlook continues to show positive growth, driven by the expanding demand for high-performance materials across these sectors.

In 2023, the global capacity for PBT stood at approximately 2,300 KT (kilotons), and this is expected to grow to 2,900 KT by 2032, reflecting a solid expansion of production capacity. Despite the growth in production, the plant capacity utilization rate of PBT stood at 60% in 2023. This indicates the market is currently underutilized, providing an opportunity for producers to optimize operations and capitalize on increasing demand.

This article provides an in-depth PBT market outlook, examining the key drivers of demand, regional insights, applications, and challenges facing the market. By providing actionable insights, real-world examples, and future-forward analysis, this article aims to offer a comprehensive understanding of the PBT market’s supply and demand dynamics.

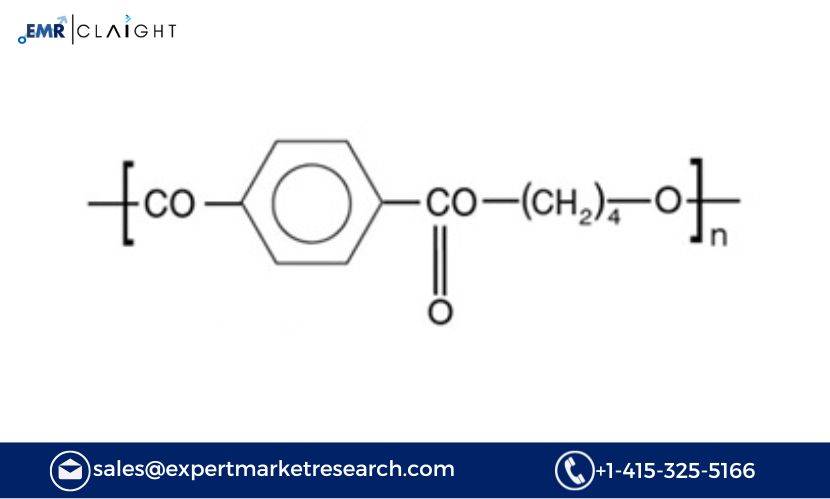

What is Polybutylene Terephthalate (PBT)?

Polybutylene Terephthalate (PBT) is a highly crystalline and thermally stable polyester polymer made by the polymerization of butylene glycol and terephthalic acid. The material is characterized by its outstanding electrical properties, resistance to chemicals, low moisture absorption, and high strength. These properties make PBT an ideal choice for high-performance engineering applications, where durability and long-term reliability are essential.

Some of the critical characteristics of PBT include:

- High mechanical strength: PBT is strong and durable, making it suitable for use in structural applications.

- Excellent electrical insulation: PBT is commonly used in electronics and electrical components due to its superior insulation properties.

- Chemical and heat resistance: PBT exhibits resistance to a broad range of chemicals, oils, and high temperatures, contributing to its longevity in challenging environments.

PBT is used in various applications, ranging from automotive parts to consumer electronics, electrical components, and industrial machinery. Its growing adoption in the automotive and electronics industries is one of the primary drivers behind the expanding market.

Get a Free Sample Report with Table of Contents@

Key Drivers of Demand for Polybutylene Terephthalate

1. Automotive Industry

The automotive industry has long been a significant consumer of PBT, and its demand is projected to continue growing. PBT is used in manufacturing a wide range of automotive parts, including connectors, switches, and under-the-hood components, where durability and heat resistance are critical. As the automotive industry shifts toward more fuel-efficient and electric vehicles, there is a growing demand for lightweight and durable materials. PBT meets these requirements by reducing the overall weight of vehicles without sacrificing performance, making it an ideal choice for automakers.

Moreover, PBT’s high-temperature resistance makes it suitable for applications in the engine compartment, which is subject to extreme temperatures. The demand for lighter and more efficient electric vehicles (EVs) also increases the need for advanced materials such as PBT to ensure high performance, energy efficiency, and durability.

2. Electronics and Electrical Components

The demand for PBT in electronics and electrical components is another significant factor propelling the market’s growth. PBT is commonly used to manufacture connectors, switches, and housings for electronic devices due to its excellent electrical insulation properties. As the global electronics industry expands—particularly with the rise of IoT (Internet of Things), smart homes, and wearable devices—the demand for PBT is expected to rise.

In addition, the growing reliance on electrical components in consumer electronics, such as smartphones, laptops, and home appliances, is further boosting demand. The material’s ability to provide thermal stability and electrical insulation makes it essential for ensuring the longevity and safety of these devices.

3. Consumer Goods and Industrial Applications

PBT is also used in consumer goods and industrial applications, where it is valued for its strength, durability, and resistance to wear and tear. It is commonly used in the production of housings for household appliances, such as vacuum cleaners, kitchen gadgets, and power tools. Additionally, it is used in industrial components like pumps, valves, and connectors, thanks to its resistance to chemical corrosion and ability to withstand harsh operating environments.

As demand for durable, high-performance products continues to rise, the market for PBT will expand across these sectors.

Regional Insights and Market Dynamics

1. Asia Pacific: Dominant Market

Asia Pacific is the largest consumer of PBT, accounting for more than half of the global market share. This is primarily due to the strong manufacturing base in countries like China, Japan, and South Korea, where there is significant demand for PBT in the automotive, electronics, and consumer goods sectors. The region is home to some of the world’s largest automotive manufacturers, such as Toyota, Honda, and Hyundai, which are increasingly adopting PBT in their products.

In addition, China is a key market for PBT, both as a consumer and producer. The growing demand for electric vehicles and electronics in China is expected to further boost the demand for PBT. As a result, the region will continue to dominate the PBT market in the coming years.

2. North America: Steady Demand Growth

In North America, the demand for PBT is primarily driven by the automotive, electronics, and consumer goods sectors. The U.S. remains one of the largest consumers of PBT due to its well-established manufacturing base and growing focus on energy-efficient vehicles. As automakers in North America continue to embrace electric vehicles, the demand for lightweight and durable materials like PBT is expected to grow.

Additionally, the growing reliance on smart devices and electronics in the region further supports the demand for PBT, particularly in the production of electrical components and consumer electronics.

3. Europe: Increasing Demand in Automotive and Electronics

Europe has a well-established automotive industry, with a growing focus on electric vehicles and advanced technology. Countries like Germany, France, and the U.K. are key players in the PBT market, where the material is widely used in automotive components and electronic devices. Europe’s emphasis on sustainability and energy-efficient products is likely to continue driving the demand for lightweight, high-performance materials such as PBT.

4. Middle East and Africa: Emerging Markets

While the Middle East and Africa currently account for a smaller portion of the global PBT market, the region is expected to experience significant growth over the next decade. As industrialization and infrastructure development accelerate in countries like Saudi Arabia, the UAE, and South Africa, the demand for PBT in automotive, electronics, and industrial applications is expected to rise.

Challenges and Opportunities in the PBT Market

1. Raw Material Price Volatility

The price of PBT is closely linked to the cost of its raw materials, primarily terephthalic acid (TPA) and butylene glycol (BG), which are subject to fluctuations in the petrochemical industry. Volatility in the price of crude oil and related feedstocks can affect the overall production cost of PBT. Manufacturers must closely monitor these price changes and explore strategies such as vertical integration or alternative feedstocks to mitigate the impact of raw material price volatility.

2. Environmental Regulations

With growing awareness of environmental sustainability, governments around the world are imposing stricter regulations on plastic production and disposal. The PBT market may face challenges as stricter waste management laws and recycling requirements come into play. However, these challenges present opportunities for innovation, as manufacturers can explore more sustainable production processes and develop recyclable versions of PBT to align with global sustainability goals.

3. Technological Advancements

The future of the PBT market will be shaped by technological advancements, particularly in the automotive and electronics sectors. As industries continue to focus on energy efficiency, sustainability, and performance, PBT manufacturers will need to innovate and adapt to new technologies. Innovations in PBT production, such as reducing energy consumption, improving material properties, and enhancing recyclability, will help players in the market stay competitive.

Future Outlook for the PBT Market

The Polybutylene Terephthalate (PBT) market outlook remains positive, with steady growth projected in the coming years. As of 2023, the global PBT production capacity was approximately 2,300 KT, and this is expected to reach 2,900 KT by 2032. With an average plant capacity utilization rate of 60% in 2023, there is significant potential for market growth as demand for PBT increases, particularly in the automotive, electronics, and consumer goods industries.

The rising adoption of electric vehicles, growing demand for high-performance materials, and technological innovations will all contribute to the continued expansion of the PBT market. Manufacturers that focus on improving production efficiency, sustainability, and material performance will be well-positioned to capture a larger share of the global market.

In conclusion, the PBT market is set to experience robust growth, driven by increasing demand across key industries. Stakeholders in the supply chain, from raw material suppliers to end-product manufacturers, must stay ahead of evolving trends to maximize opportunities in the expanding PBT market.

Related Reports

https://www.expertmarketresearch.com/articles/top-natural-rubber-companies

Media Contact

Company Name: Claight Corporation

Contact Person: Peter Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au