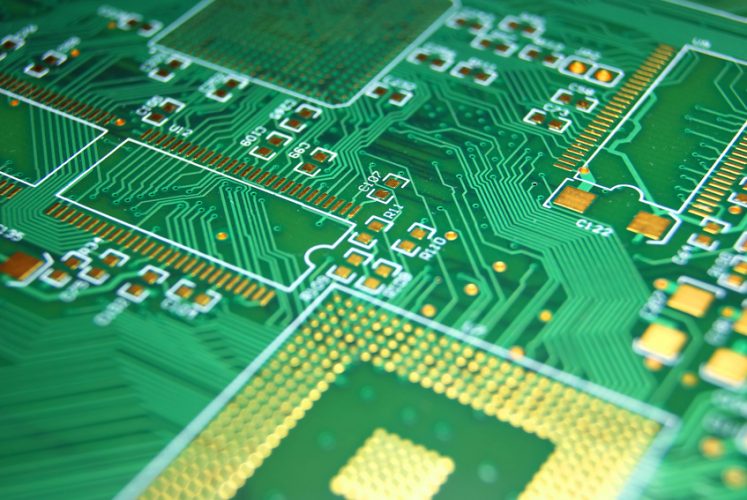

In the rapidly evolving world of technology, turning innovative ideas into tangible products is essential for staying competitive. This is where PCB prototypes come into play. Printed Circuit Board (PCB) prototypes are fundamental in transforming abstract concepts into working models that can be tested, evaluated, and refined. This blog post explores how PCB prototypes facilitate this transformation, the advantages they offer, and how to effectively utilize them in your product development process.

What are PCB Prototypes?

PCB prototypes are initial versions of printed circuit boards used to test and validate electronic designs before full-scale production. They allow engineers and designers to assess functionality, detect issues, and refine their designs based on real-world testing. By creating a prototype, teams can ensure that the final product meets specifications and functions as intended.

The Importance of PCB Prototypes in Product Development

Rapid Testing and Iteration

One of the primary benefits of PCB prototypes is the ability to test designs quickly. Rapid prototyping enables teams to produce a working model of their electronic device within a short timeframe. This fast turnaround allows for multiple iterations, giving engineers the flexibility to make adjustments based on testing feedback.

When ideas can be tested and validated quickly, the overall development process becomes more efficient. Instead of waiting weeks or months for the first prototype, teams can quickly see how their designs hold up under real-world conditions.

Cost Efficiency

Investing in PCB prototypes can save significant costs in the long run. Traditional production methods in the PCBA Factory often require large upfront investments, including material costs and labor for full-scale manufacturing. By first creating a prototype, companies can identify potential design flaws and make necessary adjustments before committing to large-scale production.

This approach minimizes waste and reduces the likelihood of expensive recalls or redesigns once the product hits the market. Ultimately, this means that companies can allocate their resources more effectively, ensuring that they only invest in designs that have been thoroughly tested and validated.

Enhanced Collaboration

Creating PCB prototypes fosters collaboration among team members. Having a physical model to examine allows engineers, designers, and stakeholders to engage in more productive discussions. They can identify issues, brainstorm solutions, and collectively refine the design.

Collaboration becomes especially important in complex projects where multiple disciplines intersect. For instance, software and hardware engineers need to work together closely to ensure that the final product integrates seamlessly. Prototyping promotes this collaboration, leading to more innovative and effective solutions.

Improved Quality Control

PCB prototypes enable better quality control throughout the product development process. By testing prototypes, teams can assess how well the design performs under various conditions and identify any weaknesses or points of failure. This proactive approach to quality assurance helps ensure that the final product meets industry standards and customer expectations.

With continuous testing and refinement, companies can enhance the overall reliability of their products, which is critical in sectors like automotive, aerospace, and medical devices where safety and performance are paramount.

Faster Time-to-Market

In today’s fast-paced market, getting a product to consumers quickly can be a significant advantage. Utilizing PCB prototypes allows companies to shorten their development cycles, leading to faster time-to-market. When products can be developed, tested, and refined rapidly, businesses can respond more swiftly to consumer demands and market trends.

This speed can be a crucial differentiator in competitive industries, where early adopters often gain significant market share. By investing in rapid prototyping processes, companies can capitalize on emerging opportunities and position themselves as leaders in their fields.

Best Practices for Utilizing PCB Prototypes

To make the most out of your PCB prototypes, consider the following best practices:

Define Clear Objectives: Before starting the prototyping process, outline your goals and objectives. What are you trying to achieve with your prototype? Understanding your goals will help guide the design and testing process.

Leverage Advanced Prototyping Technologies: Take advantage of modern prototyping technologies such as 3D printing and advanced PCB design software. These tools can streamline the prototyping process and enhance the precision of your designs.

Engage Stakeholders Early: Involve key stakeholders in the prototyping process from the outset. Their insights can provide valuable perspectives that may improve the final design. Regular check-ins and collaborative feedback sessions can foster better communication and alignment among teams.

Test Thoroughly: Don’t skimp on testing your PCB prototypes. Conduct a variety of tests to assess performance, reliability, and compliance with relevant standards. The more comprehensive your testing, the better prepared you’ll be for full-scale production.

Iterate Based on Feedback: Use the feedback gathered during testing to inform your design iterations. Be open to making changes based on what you learn; flexibility is key to successful prototyping.

Conclusion

In conclusion, PCB prototypes are a vital part of the product development process, enabling companies to transform innovative ideas into tangible solutions quickly and efficiently. The benefits of rapid testing, cost efficiency, enhanced collaboration, improved quality control, and faster time-to-market make them an invaluable asset in today’s competitive landscape.

By following best practices and leveraging the capabilities of modern prototyping technologies, businesses can maximize the effectiveness of their PCB prototypes and drive their innovations forward. If you’re ready to explore how PCB prototyping can transform your product development process, click this link here now to learn more about the latest trends and technologies in PCB design and manufacturing. Embrace the power of prototyping and unlock your potential for innovation!

52 Comments

사기 걱정 없는 먹튀검증, 토토검증소와 함께하세요.

먹튀검증 선택, 이제는 전문가의 손길이 필요합니다.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://accounts.binance.com/es/register?ref=T7KCZASX

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/en-IN/register?ref=UM6SMJM3

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/id/register-person?ref=GJY4VW8W

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your enticle? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks!