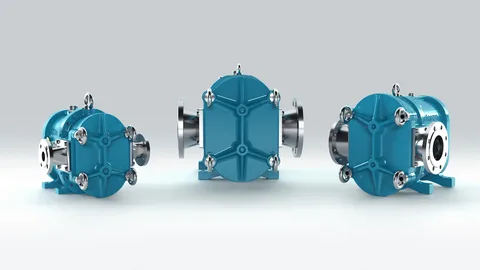

Rotary lobe pumps are versatile, efficient, and reliable, making them indispensable in various industries. These pumps handle a wide range of viscosities and solids, ensuring optimal performance across different applications. Their gentle pumping action and hygienic properties make them ideal for industries requiring high levels of sanitation and precision. Below, we explore the top five industries that significantly benefit from rotary lobe pumps.

Food and Beverage Industry

The food and beverage industry relies heavily on rotary lobe pumps for their ability to handle viscous and shear-sensitive products. These pumps can transfer products like yogurt, sauces, syrups, and dairy products without compromising their texture and quality. Their gentle handling ensures minimal degradation of the pumped material, maintaining the integrity of delicate food products.

Furthermore, rotary lobe pumps meet stringent hygiene standards, making them ideal for food processing. Their stainless-steel construction and easy-to-clean design prevent contamination and facilitate compliance with food safety regulations. The ability to handle both low and high-viscosity products while ensuring product purity makes these pumps a staple in food production lines.

Pharmaceutical and Biotechnology Industry

In the pharmaceutical and biotechnology industry, precision and hygiene are paramount. Rotary lobe pumps play a crucial role in transferring sensitive biological materials, liquid medicines, and creams. Their ability to provide consistent flow rates without causing shear stress makes them perfect for maintaining the efficacy of pharmaceutical formulations.

Additionally, these pumps adhere to strict sanitary requirements, including Clean-in-Place (CIP) and Sterilize-in-Place (SIP) capabilities. Their smooth, crevice-free surfaces prevent bacterial growth, ensuring compliance with Good Manufacturing Practices (GMP). The pharmaceutical industry benefits from the reliability and precision of rotary lobe pumps in drug production and research applications.

Dairy and Dairy Processing Industry

Rotary lobe pumps are widely used in the dairy industry for handling milk, cream, cheese curds, and yogurt. Their ability to transfer high-viscosity products without causing damage makes them ideal for dairy processing applications. They also ensure that sensitive dairy products retain their consistency and nutritional value during transportation.

The dairy industry benefits from the hygienic design of rotary lobe pumps, which minimizes the risk of contamination. Their ability to maintain a high degree of cleanliness, combined with ease of maintenance, makes them a reliable choice for dairy manufacturers looking to streamline their processing operations while ensuring product quality and safety.

Chemical and Petrochemical Industry

The chemical and petrochemical industry requires pumps that can handle aggressive and corrosive substances safely. Rotary lobe pumps excel in transferring a wide range of chemicals, including acids, solvents, and resins, with minimal risk of leakage. Their robust construction ensures durability even in harsh chemical environments.

Moreover, rotary lobe pumps provide accurate dosing and metering, essential for chemical processing. Their precise flow control and resistance to chemical corrosion make them an excellent choice for handling specialty chemicals, adhesives, and industrial lubricants. The ability to operate efficiently in hazardous environments further enhances their value in this sector.

Wastewater and Environmental Industry

The wastewater and environmental industry benefits from rotary lobe pumps due to their ability to handle sludge, slurries, and other viscous waste materials efficiently. These pumps play a critical role in sewage treatment plants, helping transport thick, solid-laden liquids without clogging or losing efficiency.

Additionally, rotary lobe pumps contribute to sustainable waste management by enabling efficient water treatment processes. Their energy efficiency and minimal maintenance requirements make them a cost-effective solution for wastewater treatment facilities. By providing consistent and reliable performance, these pumps help industries meet environmental regulations and sustainability goals.

Conclusion

Rotary lobe pumps have become an essential component in various industries due to their versatility, efficiency, and ability to handle diverse fluids. From food processing and pharmaceuticals to wastewater treatment, these pumps offer hygienic, durable, and reliable solutions for fluid transfer. Their ability to provide precise flow control, resist contamination, and operate efficiently in challenging environments makes them invaluable across multiple sectors. As industries continue to evolve, the demand for high-performance rotary lobe pumps will only grow, solidifying their role as a crucial asset in industrial operations.