In the world of surgical instruments, one name stands out as a global leader Sialkot, Pakistan. Known for its high-quality craftsmanship, Sialkot has become the primary hub for surgical instrument manufacturing, supplying top-tier products to hospitals and medical institutions worldwide. With a long history of specialized production and a commitment to excellence, Sialkot plays a crucial role in the global healthcare supply chain, offering precision made instruments that are trusted by medical professionals around the globe.

History of Surgical Instruments Manufacturing in Sialkot

Surgical Instruments Manufacturers in Sialkot reputation as a manufacturing hub dates back over a century. Initially, it started as a center for cutlery and blade manufacturing, which then evolved to include surgical instruments. By the mid-20th century, Sialkot’s craftsmen had begun producing surgical tools, capitalizing on their expertise in metalwork and craftsmanship. Over the years, this industry has grown, gaining a stellar reputation for quality and innovation, making Sialkot synonymous with reliable and precision-crafted surgical instruments.

Why Sialkot is the Global Leader in Surgical Instrument Manufacturing

High-Quality Craftsmanship and Skilled Labor

Sialkot’s workforce has unparalleled expertise, with skills passed down through generations. The city’s artisans are renowned for their attention to detail, precision, and commitment to quality, setting a standard that few regions can match.

Technological Advancements and Innovation

Sialkot has embraced technology, integrating modern machinery and automation with traditional craftsmanship. This balance allows manufacturers to produce instruments that are both high-quality and cost-effective, meeting the demands of modern medical fields.

Competitive Pricing and Export Strength

One of Sialkot’s major strengths is its ability to offer high-quality products at competitive prices. The combination of skilled labor and economic efficiencies allows Sialkot’s manufacturers to remain affordable, making the city an attractive option for hospitals and medical supply chains globally.

Types of Surgical Instruments Manufactured in Sialkot

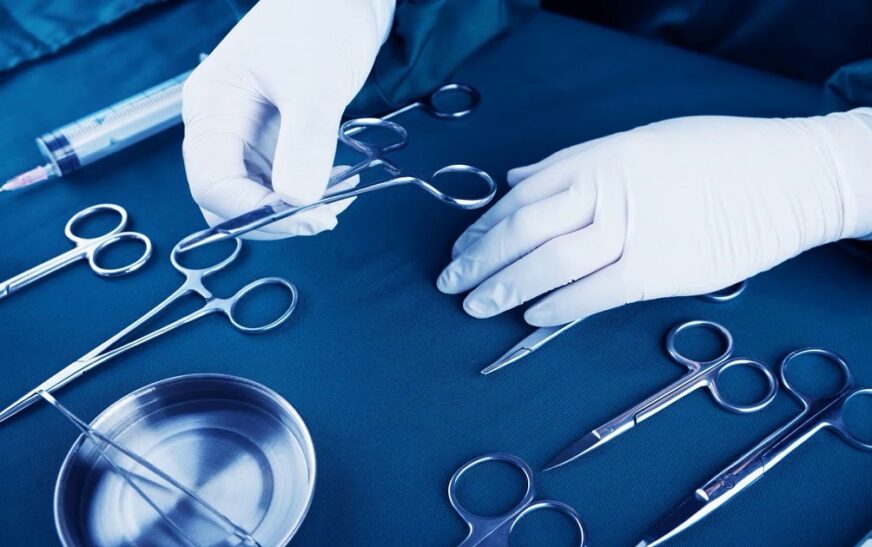

General Surgery Instruments

These include scalpels, forceps, retractors, and scissors, essential for almost every surgical procedure.

Dental Instruments

Sialkot produces specialized tools for dental surgeries, such as dental pliers, mirrors, and probes, which are critical for oral health professionals.

Orthopedic Instruments

Orthopedic tools like bone saws, drills, and fixation devices are manufactured to high standards, supporting both invasive and minimally invasive procedures.

Ophthalmic Instruments

For eye surgeries, precise tools like micro-scissors and forceps are crafted to meet the delicate requirements of ophthalmology.

Veterinary Instruments

Instruments for veterinary surgery, such as forceps, needles, and scissors, are also produced, serving the needs of the global veterinary community.

Key Manufacturing Processes Used in Sialkot

Precision Forging and Machining

Forging and machining are central to Sialkot’s manufacturing, with specialized equipment ensuring the instruments are durable and precise.

Laser Cutting and Finishing Techniques

Laser technology is used for accurate cutting, while advanced finishing techniques give the instruments a smooth, corrosion-resistant surface.

Heat Treatment and Quality Assurance

Heat treatment strengthens the instruments, making them resistant to wear and ensuring they can withstand sterilization processes.

Quality Standards and Certifications

Importance of International Quality Certifications (ISO, CE, FDA)

Sialkot’s manufacturers adhere to stringent international standards, including ISO and CE certifications, which attest to the quality and safety of their products. Many companies also meet FDA standards, making their instruments trusted in North America and Europe.

How Sialkot Manufacturers Meet Global Standards

Manufacturers regularly undergo audits, update production processes, and invest in high-quality materials to meet and exceed these global standards, ensuring reliability and safety in every product.

Role of Skilled Labor in the Industry’s Success

The development of Sialkot is largely dependent on its competent workforce. Workers here are trained extensively in the art of instrument making, with many learning from family members who have been in the industry for generations. Training programs and vocational schools further enhance the skills of the local workforce, creating a community deeply invested in the craft of surgical instrument manufacturing.

Technological Advancements and Modernization

Automation and Digital Manufacturing in Sialkot

To keep up with international demand, many manufacturers in Sialkot have embraced automation, incorporating digital systems that improve efficiency and precision. This modernization allows for consistent quality across large production runs.

Advanced Materials and Innovations in Design

Manufacturers are also experimenting with new materials, such as titanium and specialized stainless steels, that are lighter, stronger, and more resistant to corrosion, meeting the evolving demands of modern surgery.

Economic Impact of the Surgical Instruments Industry on Sialkot

Contribution to Local Employment and Economy

The surgical instruments industry provides jobs to thousands of people in Sialkot, from skilled labor to administrative roles, significantly impacting the local economy.

Export Revenue and Economic Benefits

The industry brings in substantial foreign revenue, with exports primarily directed toward North America, Europe, and the Middle East. This export strength has made Sialkot a cornerstone of Pakistan’s economy.

Sustainability and Ethical Practices

Environmental Efforts and Waste Reduction

Many manufacturers in Sialkot are adopting eco-friendly practices, such as waste reduction programs and using sustainable materials wherever possible.

Ensuring Fair Labor Practices in the Manufacturing Process

Ethical practices are increasingly important, with companies focusing on fair wages, safe working conditions, and social responsibility initiatives.

Key Export Markets for Sialkot’s Surgical Instruments

The United States, the United Kingdom, Germany, and the Middle East are among Sialkot’s principal markets. Trade fairs, exhibitions, and international partnerships have further boosted Sialkot’s global reach, establishing it as a trusted provider in these regions.

Challenges Facing the Industry

Increasing Global Competition

With emerging competitors, Sialkot must continuously innovate and improve its efficiency to stay ahead.

Adapting to New Regulatory Demands and Standards

With international standards evolving, Sialkot’s manufacturers face the challenge of keeping up with new requirements, which may require further investment in technology and training.

Economic Fluctuations and Impact on Manufacturing Costs

Global economic changes can impact production costs, forcing manufacturers to find new ways to maintain profitability.

Conclusion

Sialkot’s surgical instruments industry has established itself as a global leader through a blend of craftsmanship, quality, and innovation. Despite challenges, the industry remains robust, contributing significantly to the local economy and meeting the needs of healthcare providers worldwide. With continued investment in technology and training, Sialkot is well-positioned for a prosperous future in surgical instrument manufacturing.

FAQs

Q1: Why is Sialkot known for surgical instruments manufacturing?

A: Sialkot has a long history of craftsmanship in metalwork, skilled labor, and a commitment to quality, making it a trusted global hub for surgical instruments.

Q2: What types of instruments are primarily produced in Sialkot?

A: Sialkot manufactures a wide range of instruments, including general surgery, dental, orthopedic, ophthalmic, and veterinary tools.

Q3: How do Sialkot manufacturers maintain quality standards?

A: They adhere to international standards, such as ISO and CE, and undergo frequent audits and inspections to ensure high-quality production.

Q4: Who are the major importers of Sialkot’s surgical instruments?

A: The major markets include the United States, Europe, and the Middle East, where Sialkot’s instruments are trusted in various medical fields.

Q5: What challenges does the Sialkot industry face?

A: Increasing competition, regulatory changes, and economic fluctuations are some challenges, but Sialkot manufacturers are constantly innovating to overcome these hurdles.

49 Comments

магазин аккаунтов услуги по продаже аккаунтов

биржа аккаунтов заработок на аккаунтах

платформа для покупки аккаунтов маркетплейс аккаунтов

биржа аккаунтов магазин аккаунтов социальных сетей

заработок на аккаунтах безопасная сделка аккаунтов

Buy Account Secure Account Purchasing Platform

Account Trading Platform Gaming account marketplace

Account marketplace Find Accounts for Sale

Account Selling Platform Buy Account

Account Sale Account exchange

Secure Account Sales Account Trading Platform

Buy Pre-made Account Sell accounts

Guaranteed Accounts Purchase Ready-Made Accounts

Account Store Online Account Store

Online Account Store https://socialmediaaccountsale.com/

social media account marketplace https://cheapaccountsmarket.com

account exchange service buy and sell accounts

sell pre-made account ready-made accounts for sale

profitable account sales account buying service

guaranteed accounts online account store

sell pre-made account purchase ready-made accounts

account purchase accountsmarketdiscount.com

sell accounts accounts marketplace

account exchange service verified accounts for sale

buy and sell accounts https://accounts-marketplace.org

account store account sale

gaming account marketplace account exchange

profitable account sales secure account purchasing platform

ready-made accounts for sale account selling platform

accounts marketplace account catalog

accounts market database of accounts for sale

buy account online account store

account buying platform account trading platform

verified accounts for sale buy accounts

online account store account purchase

account trading platform account marketplace

website for buying accounts account selling platform

social media account marketplace website for selling accounts

social media account marketplace account trading platform

account purchase account exchange

account buying service online account store

account exchange service verified accounts for sale

buy account https://accounts-offer.org

account exchange accounts-marketplace.xyz

verified accounts for sale buy-best-accounts.org

verified accounts for sale https://social-accounts-marketplaces.live

marketplace for ready-made accounts https://accounts-marketplace.live

account exchange service https://social-accounts-marketplace.xyz

account trading https://buy-accounts.space