Introduction

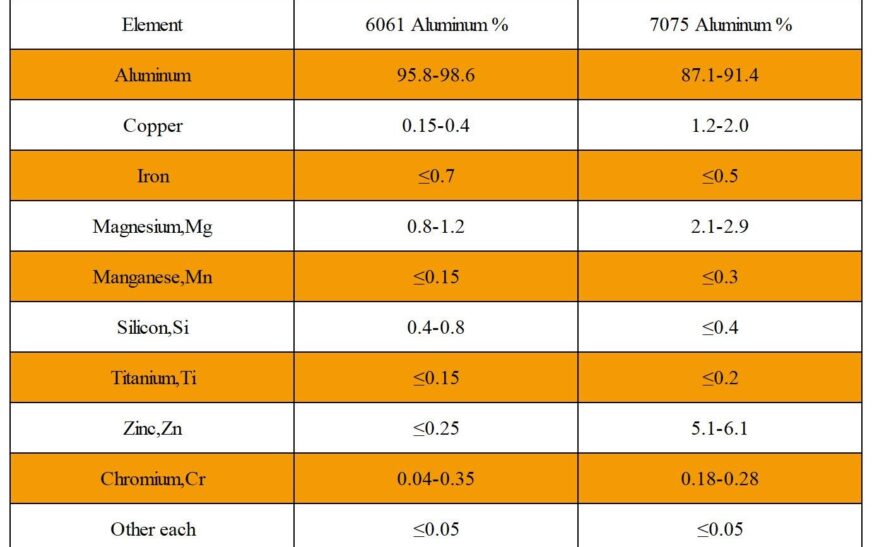

When it comes to choosing materials for manufacturing and engineering projects, the decision often boils down to specific properties like strength, durability, workability, and corrosion resistance. Among the wide range of materials available, 6061 and 7075 aluminum alloys are two of the most widely used in industries such as aerospace, automotive, and construction. Both alloys have their unique features and advantages, making them suitable for different applications. However, understanding the key differences between 6061 and 7075 aluminum is essential for choosing the right material for a given project.

In this article, we will explore the similarities and differences between 6061 vs 7075 aluminum alloys, comparing their chemical composition, mechanical properties, applications, and more. This guide will help you understand which alloy is best suited for your specific needs.

What are 6061 and 7075 Aluminum Alloys?

Before diving into the comparison, let’s first understand what 6061 and 7075 aluminum alloys are, and how they are classified.

6061 Aluminum Alloy

6061 aluminum alloy is one of the most versatile and widely used alloys in the aluminum series. It is classified as a heat-treatable alloy, primarily composed of aluminum, magnesium, and silicon. 6061 aluminum is known for its excellent combination of strength, corrosion resistance, and workability, making it a popular choice for applications ranging from structural components to consumer goods.

This alloy is commonly used in industries such as aerospace, marine, construction, and automotive, where it offers a balance of strength and weight. Its ease of fabrication makes it a go-to material for many different types of projects, including welding, extrusion, and machining.

7075 Aluminum Alloy

7075 aluminum alloy is a high-strength aluminum alloy that is primarily composed of zinc, with smaller amounts of magnesium and copper. It is one of the strongest aluminum alloys available, making it highly sought after in demanding applications like aerospace, military, and high-performance engineering. Due to its strength-to-weight ratio, 7075 aluminum is often used in the production of parts where high strength is critical without adding significant weight.

While 7075 aluminum offers superior strength compared to 6061, it is somewhat less corrosion-resistant and more difficult to machine, making it more specialized for applications requiring extreme strength.

Key Differences Between 6061 and 7075 Aluminum Alloys

To better understand when to use each alloy, we’ll compare their key properties, including mechanical properties, corrosion resistance, machinability, weldability, and cost.

1. Mechanical Properties

One of the most important factors when selecting an aluminum alloy is its mechanical properties, such as tensile strength, yield strength, and hardness. Here’s how 6061 and 7075 compare:

- 6061 Aluminum:

- Tensile Strength: 290 MPa (42,000 psi)

- Yield Strength: 240 MPa (35,000 psi)

- Hardness: Brinell hardness of 95

- 7075 Aluminum:

- Tensile Strength: 572 MPa (83,000 psi)

- Yield Strength: 503 MPa (73,000 psi)

- Hardness: Brinell hardness of 150

From the data, it’s clear that 7075 aluminum is significantly stronger than 6061. This makes 7075 ideal for applications that require high strength, such as aerospace and military components. 6061, on the other hand, has a more moderate strength level and is well-suited for general-purpose applications.

2. Corrosion Resistance

Corrosion resistance is a crucial factor when selecting materials for outdoor or marine environments, where exposure to the elements can degrade metal components over time.

- 6061 Aluminum: 6061 is known for its excellent corrosion resistance, particularly when anodized or treated with protective coatings. It performs well in marine environments and other conditions where exposure to moisture and salt is common.

- 7075 Aluminum: While 7075 has good corrosion resistance compared to other materials, it is less resistant than 6061, particularly when exposed to saltwater or harsh environments. As such, 7075 typically requires additional coatings or anodizing to ensure optimal corrosion protection in these conditions.

In general, 6061 is the better choice for environments where corrosion resistance is a top priority.

3. Machinability

Machinability refers to how easily a material can be shaped, cut, and formed into the desired part. This property is crucial for industries where complex parts are fabricated.

- 6061 Aluminum: 6061 is known for its excellent machinability, allowing it to be easily welded, cut, drilled, and extruded. The alloy’s moderate strength makes it easier to machine and shape compared to stronger alloys, which is why it is often chosen for custom and low-volume manufacturing.

- 7075 Aluminum: While 7075 is a high-strength alloy, its strength can make it more challenging to machine, requiring specialized tools and techniques. The alloy is more prone to work hardening, which can make machining difficult and time-consuming. Despite this, 7075 is still machinable with the right equipment and processes.

For ease of machining and fabrication, 6061 aluminum is generally preferred unless extreme strength is required.

4. Weldability

Weldability is another important consideration, especially for industries like construction, where welding is a common part of the fabrication process.

- 6061 Aluminum: 6061 aluminum is known for its excellent weldability. It can be easily welded using techniques like MIG (metal inert gas) and TIG (tungsten inert gas) welding. However, it is important to note that heat treatment can affect its strength after welding, so additional post-weld treatments may be necessary to maintain optimal strength.

- 7075 Aluminum: Welding 7075 aluminum is more challenging than welding 6061. The alloy’s high strength can cause issues with cracking during the welding process. Special techniques, such as preheating and post-weld heat treatment, are required to achieve a high-quality weld with 7075 aluminum. As a result, it is typically not used in applications that require extensive welding.

For applications where welding is a key factor, 6061 aluminum is the better choice due to its superior weldability.

5. Cost

Cost is often a deciding factor in material selection, especially for larger-scale projects.

- 6061 Aluminum: Generally, 6061 is less expensive than 7075, making it a more economical choice for applications that don’t require the extreme strength of 7075. Its widespread use and versatility also contribute to its lower cost.

- 7075 Aluminum: Due to its superior strength and specialized applications, 7075 is more expensive than 6061. The cost reflects the alloy’s higher performance, but it may not be cost-effective for projects that do not require its high-strength properties.

6. Applications

Both alloys have unique applications based on their properties:

- 6061 Aluminum:

Commonly used in aerospace, automotive, construction, marine, and general engineering applications. It is often found in parts like frames, bicycle components, aircraft fittings, structural elements, and outdoor furniture. - 7075 Aluminum:

Primarily used in aerospace, military, and high-performance engineering applications, including aircraft wings, missile parts, marine structures, and military vehicles. It is used when high strength and light weight are paramount.

Conclusion

Choosing between 6061 and 7075 aluminum alloys ultimately depends on the specific needs of the project. If strength is the primary concern, especially in applications like aerospace and military equipment, 7075 is the superior choice due to its high strength-to-weight ratio. However, for general-purpose applications that require a balance of strength, corrosion resistance, and machinability, 6061 is often the more suitable and cost-effective option.

In summary:

- 6061 Aluminum is an excellent all-rounder, offering moderate strength, good corrosion resistance, ease of machining, and weldability at a lower cost.

- 7075 Aluminum excels in strength and is ideal for high-performance, weight-sensitive applications but requires more careful handling during machining and welding and comes at a higher cost.

By understanding the differences between these two alloys, you can make a more informed decision about which material is best suited for your specific project needs.

16 Comments

Mostbet kasyno online przyciąga atrakcyjnymi promocjami | Czy warto wybrać Mostbet? Opinie graczy mówią same za siebie | Mostbet Polska stale rozwija swoją ofertę dla graczy z Polski Mostbet login Polska

Ten serwis świetnie porównuje oferty bonusów kasynowych | Strona pomaga wybrać najlepsze zakłady bukmacherskie w Polsce | Dobry wybór kasyn z darmowymi spinami | Opcja filtrowania kasyn według metod płatności – super | Kasyna dostępne na urządzeniach mobilnych – to duży plus | Funkcjonalna wyszukiwarka kodów promocyjnych | Często aktualizowane bonusy i promocje | Kasyno online z najlepszymi ocenami – wszystko jasne | Kasyno online z najlepszym wyborem gier kasyno vulkan vegas.

Mostbet to legalne kasyno online dostępne dla graczy z Polski. | Graj odpowiedzialnie i korzystaj z narzędzi kontroli w Mostbet. | Mostbet posiada licencję gwarantującą uczciwość gier. | Mostbet zapewnia szybkie wypłaty wygranych na Twoje konto. mostbet logowanie

Zkuste štěstí na Mostbet online je to snadné | Užijte si sportovní sázky na Mostbet cz | Většina hráčů doporučuje Mostbet mostbet site.

Pinco az-da qeydiyyatdan keçmək cəmi bir neçə dəqiqə çəkir|Pinco bonusları hər bir istifadəçiyə təqdim olunur|Pinco oyunçular üçün müxtəlif bonuslar və aksiyalar təklif edir|Pinco ilə oyun təcrübəsi maraqlı və gəlirlidir|Pinco kazinosunda oyun seçimləri çox genişdir|Pinco kazino saytı sadə və istifadəçiyə uyğundur|Pinco az onlayn kazinosunda etibarlı ödəniş üsulları var|Pinco istifadəçiləri üçün müntəzəm lotereyalar keçirilir|Pinco az oyunçularına şəxsi bonuslar təqdim edir pinco azerbaycan .

1win mobil tətbiqi ilə hər yerdə oyun oynamaq mümkündür | 1win kazino oyunlarında yüksək RTP dərəcələri mövcuddur | 1win azərbaycan platformasında müxtəlif slot oyunları mövcuddur | 1win kazino oyunlarında yüksək qazanma şansı əldə edin1win kazino oyunlarında müxtəlif jackpotlar mövcuddur | 1win-də müxtəlif idman növlərinə mərc edin1win kazino oyunlarında müxtəlif bonuslar əldə edin | 1win az saytında istifadəçilər üçün rahat interfeys mövcuddur | 1win-də müxtəlif idman növlərinə mərc edin | 1win mobil tətbiqi ilə oyun təcrübəsini artırın | 1win az saytında müxtəlif promosyonlar mövcuddur 1win qeydiyyat bonusu.

Надёжный способ купить чеки с подтверждением для отчёта. | Удобно: выбрал, оплатил, получил на почту. | Можно указать сумму, категорию расходов, дату. | Можно заказать оптом для всего отдела. | Безопасная оплата, всё официально. | Работают с разными системами налогообложения. | Поддержка работает оперативно. | Чеки всегда с актуальной датой. | Полностью соответствуют требованиям законодательства. | Доверяю этому сервису не первый раз. бухгалтерские вопросы.

Официальный сайт rox casino обновляется быстро. Есть поддержка 24/7, помогает моментально. Играть можно даже без скачивания приложения. Играю на rox casino — выигрываю и отдыхаю. Rox — надёжный выбор для игроков. Rox casino — приятный и честный сервис. Зеркало 1414 работает без перебоев. Функция быстрого пополнения доступна. Игры запускаются моментально https://casino-rox.ru/.

pinko Казахстан предлагает щедрые бонусы. Бонусы от pinko помогают увеличить шансы. pinko Казахстан предлагает выгодные условия. Пинко — отличное онлайн казино для казахстанцев. pinko — достойная альтернатива другим казино. Можно использовать промокоды на pinko. Есть демо-режим в слотах на pinko. Все данные в pinko надёжно защищены. Все популярные слоты есть на pinko казино и букмекерская пинко.

Играю в pinco уже давно и всегда доволен результатом. Pinco казино поддерживает пользователей из Кыргызстана. На сайте pinco casino часто проходят акции и турниры. Скачал приложение pinco — теперь играю где угодно. Pinco casino — отличное решение для игры на тенге. Pinco предоставляет кэшбэк и бонусы без депозита. Pinco — отличный вариант для новичков и опытных игроков. Pinco предоставляет полную статистику ставок. Выигрыши в pinco приходят очень быстро pinco скачать.

Лучшее, что видел в жанре — comatozze. Оцените comatozze full videos — кайф. Сюжеты у comatozze затягивают с первых секунд. Без пошлости, но очень откровенно — comatozze. Присоединился к фанатам comatozze. Коматоцце — это не просто видео, это стиль. Все ролики comatozze разные, но все крутые. Сайт comatozze работает отлично. Настоящая работа над образом — comatozze comatozze fans.

Explore Diana Rider’s hottest collections now | Don’t miss the bio of Diana Rider – it’s impressive. | Join thousands of Diana Rider fans online. | Discover why Diana Rider is a fan favorite | Every video by Diana Rider tells a story. | Feel the heat with Diana Rider’s newest videos. | You’ll never look at adult cinema the same – Diana Rider. | Access the full Diana Rider experience. | Diana Rider keeps it raw, real, and hot. xxx diana rider.

This is the ultimate source for Candy Love xxx videos. If you love Candy Love, don’t skip this link. Candy Love’s fans will go crazy over this update. New Candy Love scenes you didn’t know existed. Experience Candy Love like never before. The best site for Candy Love lovers. This is Candy Love’s uncensored world. From sweet to spicy — Candy Love delivers. Your Candy Love search ends here candy love hot videos.

اكتشف مجموعة Comatozze المتنوعة | أفضل لقطات Comatozze تجدها هنا | أفضل أفلام Comatozze حصرياً على الموقع | عش الإثارة مع Comatozze الآن coma tozze.

Pin Up oyna və böyük qazan!. Pin Up bonus kodları ilə daha çox qazan. Pin Up ilə yüksək mərc qazancları. Pin Up Azərbaycan oyunçuları üçün lisenziyalı kazinodur pin up giriş.

Крутые слоты и быстрые выплаты только в Lex Casino. Огромный выбор слотов и игр в Lex Casino — каждый найдет что-то по душе. Lex Casino дарит уникальные промокоды на фриспины. Хочешь фриспины? Играйте в Lex Casino!. В Lex Casino есть возможность играть на реальные деньги и выигрывать. Всем друзьям советую Lex Casino — надежное казино с бонусами lex casino играть.